NTU scientists in Singapore have developed an elastic, waterproof “tissue” that converts energy generated by body movements into electrical energy.

A main component of fabric is a polymer which, when squeezed or squeezed, converts mechanical stress into electrical energy.

It’s also made with stretchy spandex as its base layer and integrated with a rubber-like material to keep it strong, flexible, and waterproof.

In lab tests, the NTU Singapore team showed that hitting a 3 x 4 cm piece of the new fabric generated enough electrical energy to light 100 LEDs.

Washing, folding, and wrinkling of the fabric caused no degradation in performance, and was able to maintain stable electrical production for up to five months.

There have been many attempts to develop fabrics or garments that can recover the energy of movement, but a major challenge has been to develop something that does not break down in function after being washed, yet retains excellent electric power.

In our study, we show that our prototype still works well after being washed and wrinkled. We think it could be woven into T-shirts or embedded in the soles of shoes to collect energy from the body’s slightest movements, transmitting electricity to mobile devices.

Lee Pooi See, professor at NTU

The electricity-generating fabric developed by the NTU team is a energy harvesting device that converts vibrations produced by the slightest movements of the body into electricity everyday.

The fabric prototype generates electricity in two ways: when pressed or crushed (piezoelectricity), and when it comes into contact or rubs against other materialssuch as skin or rubber gloves (triboelectric effect).

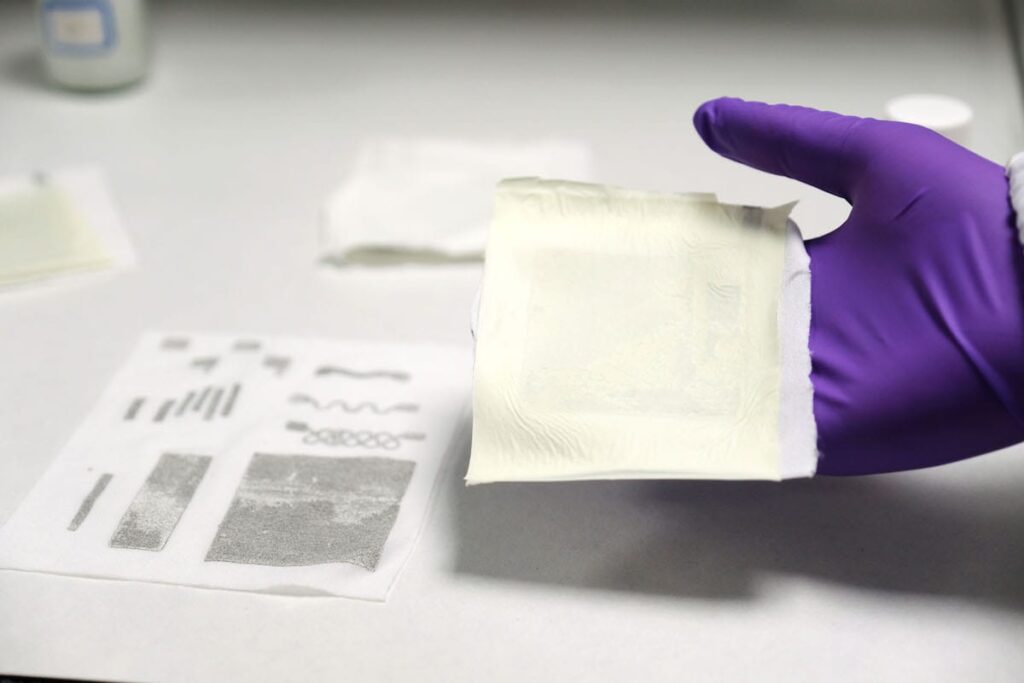

To make the prototype, the scientists first made a stretchy electrode by screen-printing an “ink” made of silver and styrene-ethylene-butylene-styrene (SEBS), a rubbery material found in the rings of teething and handlebars. stretchy and waterproof.

This stretchable electrode is then attached to a piece of nanofiber fabric made of two main components: polyvinylidene fluoride-co-hexafluoropropylene (PVDFHPF), a polymer that produces an electrical charge when compressed, bent or stretched; and lead-free perovskites, a promising material in the field of solar cells and LEDs.

The incorporation of perovskites in the PVDF-HPF increases the electrical performance of the prototype. In our study, we opted for lead-free perovskites as the most environmentally friendly option.

Although perovskites are naturally brittle, their integration into PVDF-HPF gives them exceptional mechanical durability and flexibility. PVDF-HPF also acts as an additional protective layer for perovskites, enhancing their mechanical properties and stability.

Jiang Feng, PhD student at NTU

The result is a fabric prototype that generates 2.34 watts per m2 of electricity.enough to power small electronics, such as commercial LEDs and capacitors.

To demonstrate how their fabric prototype might work, the NTU scientists showed how a hand continuously tapping a 3 x 4 cm piece of fabric could light up 100 LEDs or charge several capacitors, which are devices that store electrical energy. and are found in the devices. such as cell phones. The fabric showed good durability and stability: its electrical properties did not deteriorate after washing, folding and creasing.

Moreover, it continued to produce stable and continuous electric power for five months. Scientists have shown that their fabric can harness the energy of a range of human motion by attaching it to the arm, leg, hand and elbow, as well as the insoles of shoes, without affect movement.

Despite improved battery capacity and reduced power demand, portable device power supplies still require frequent battery replacement. Our results demonstrate that our energy-harvesting fabric prototype can harness human vibration energy to potentially extend battery life or even build self-powered systems. To our knowledge, this is the first perovskite-based hybrid energy device that is stable, stretchable, breathable, waterproof and at the same time capable of delivering extraordinary electrical performance.

Lee Pooi See

This tissue-based energy harvesting prototype builds on the work of the NTU team, which is investigating how energy generated in the environment can be harnessed. For example, the team recently developed a type of film that could be mounted on roofs or walls to harness the energy produced by wind or raindrops falling on the film. The team is currently studying how the same fabric could be adapted to harvest different forms of energy.